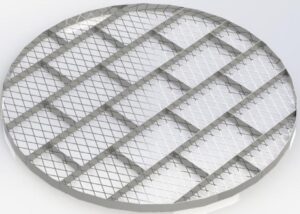

A bed limiter, also known as a bed support or packing support, is a component used in packed columns and vessels to prevent movement or settling of the packing material within the column. Its primary purpose is to maintain the integrity and effectiveness of the packed bed by confining the packing material to a specific height or location.