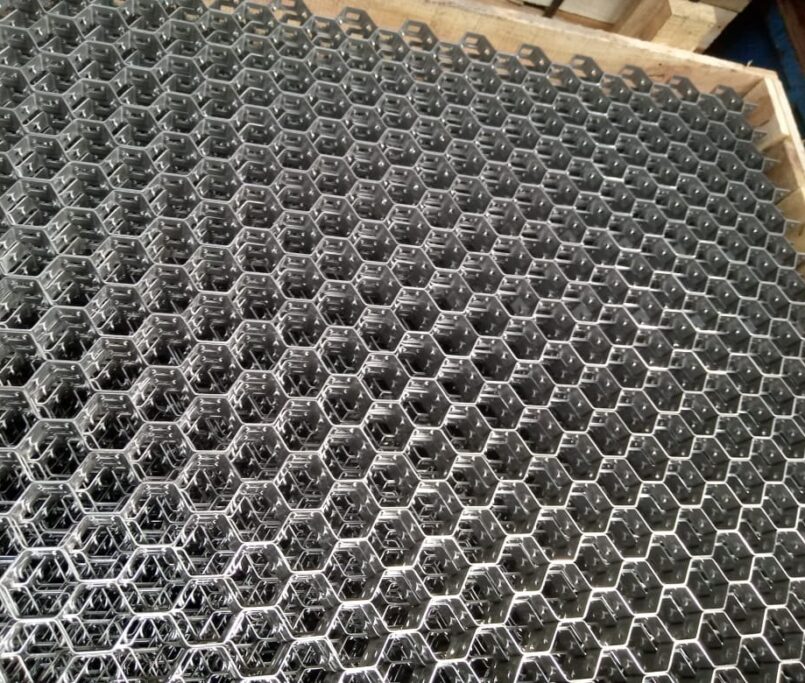

- Hexmesh can be manufactured from various materials such as stainless steel, carbon steel, and various alloys. The choice of material depends on the application’s requirements, including resistance to corrosion, heat, and other environmental factors.

- Coatings such as galvanization or special coatings may be applied to enhance the mesh’s corrosion resistance and longevity.

Hexmesh’s unique hexagonal pattern and structural properties make it versatile and effective in a wide range of industrial applications, providing stability, support, and filtration capabilities.

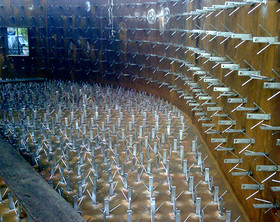

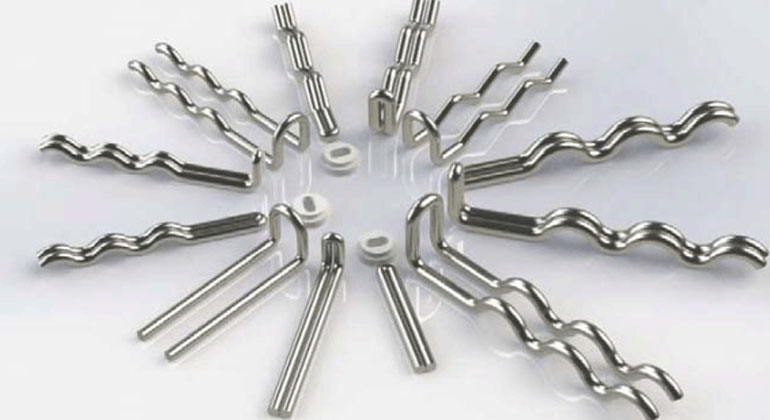

Refractory anchors are essential components used to secure refractory linings in industrial furnaces, boilers, and other high-temperature processing equipment. Refractory linings are used to protect the underlying structure from extreme temperatures, chemical corrosion, and mechanical wear. Refractory anchors help hold these linings in place and prevent them from shifting or falling off due to thermal expansion, contraction, and other stresses.