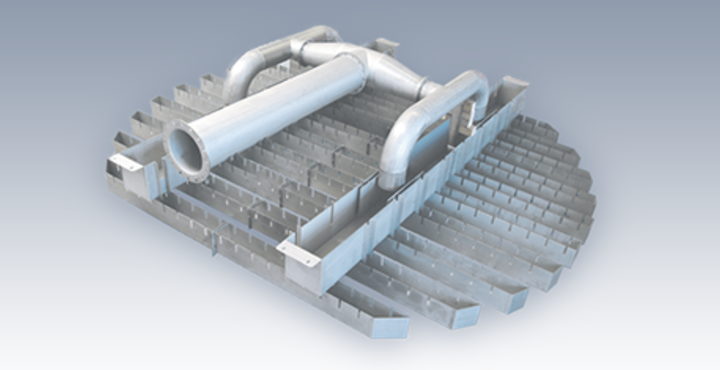

A liquid distributor is an essential component in a packed column or tower that ensures even distribution of the liquid phase across the packing surface. Proper liquid distribution is crucial for achieving efficient mass transfer and separation in distillation, absorption, and other separation processes. Here are some common types of liquid distributor column internals: